With over three decades of experience, at KGIS we offer comprehensive solutions for your heat treat requirements. We process over 1400 tons of steel every year from components varying from 10mm to 1200mm like gears, sprockets, shafts, cam shafts, connecting rods, dies, spindles, nuts, bolts etc. All the operations are performed by well trained staffs guided by experts in the field. These are some of the services that we offer at our company.

- Hardening: As the name suggests, hardening is a process done on steel to improve its hardness. The material is heated above critical temperature and held till the crystal structure changes and is quenched suddenly using water or quenching oil. This process is also called through hardening. Usually the product formed after this process is very hard and brittle. It is followed by tempering. This method is suitable for medium or high carbon steel.

- Tempering: To reduce the highly brittle and hard martensitic steel formed after the hardening, tempering is done. Tempering involves heating it to a point below the critical temperature, soaking it and allowed to cool in still air. The temperature ranges from 200ºC to 330ºC depending on composition and application. This improves the toughness of the steel and generally improves ductility and machinability of hardened steels. The time and temperature plays an important role in determining the desired properties. It also helps to relieve internal stress and obtain the required hardness.

- Annealing: is a softening process done to improve ductility, machinability, cold working, relieve stress and to remove coarseness of grains. The steel is heated 50ºC above the critical temperature and soaked in the that temperature, until re-crystallization is complete. Then it is slowly cooled usually at a specific rate inside the furnace. The result is soft and ductile steel.

- Normalizing: is the process of raising the temperature, holding it and then removed from the furnace and cooled at room temperature under natural convection. The resulting material is soft. Usually this method is preferred over annealing because it cuts down the furnace cost. It can be used where we do not need tight tolerance.

- Stress relieving: It is a technique to reduce the internal stress in the material due to cold working, non-uniform cooling, welding etc. This method involves heating the part lower than lower critical temperature and cooling uniformly.

- Carburizing: A tough core and hard outer case are desired for many applications as they undergo less wear and tear while having the resistance to impact. One of the prominent solution is Carburizing. It involves heating the steel in a carbon rich environment. This makes the carbon to diffuse to the outer surface of the steel and then it is rapidly quenched so that carbon doesn’t diffuse out forming hard outer case while the core is comparatively soft. The carburizing time and temperature determines the case depth.

- Induction hardening: Induction hardening is a faster, cheaper and more precise method of case hardening. Induction hardening uses the principles of eddy current to heat the steel to high temperature. A copper coil slightly larger than the material is placed around and high frequency current is passed. This induces eddy current on the surface of the material and gets heated to high temperature and then is quenched forming a high hardness, wear resistant case. The coil design and frequency and current amperes plays an important role on the case thickness.

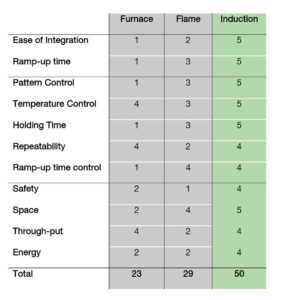

KGIS has experienced experts in the field who also fabricates coil specifically to your requirements in-house. We not only know more about induction heating than our competitors but we also know how the technology affects your materials. Induction heating offers advantage in three areas: Through-put, Quality and Safety.

- Induction Brazing: KGIS offers brazing in various important fields such as , electro technical industries. It includes brazing of aluminum, brass, copper, copper alloys, iron and cast iron, steel and stainless steel.

There are many reasons why using induction heating instead of gas for brazing is clearly beneficial. Induction transfers more energy per square meter than an open flame, resulting in faster heating cycles—put simply, you produce more components per hour.